Innovative

= DIE TRAGSCHIENE = combines the DIN mounting rail, proven a million times over, with the material and possibilities of today.

= DIE TRAGSCHIENE = combines the DIN mounting rail, proven a million times over, with the material and possibilities of today.

The wiring effort and the risk of errors are significantly reduced, an electrical enclosure is manufactured and ready for operation more quickly.

The systems with integrated signal and power lines on the market today offer less development potential and have significantly higher total cost of ownership as an integrated system made of plastic.

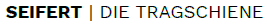

Often there is a general need to reduce effort and improve performance at the beginning, without it being clear what exactly is to be optimised and how. In this case, it is worthwhile to examine the current situation in detail and to describe the goal

In = DIE TRAGSCHIENE = Master's Thesis, concepts were developed, visualised, compared, evaluated and finally selected for in-depth work.

Now all the work is done, beautiful pictures alone are no longer enough. You as the development partner say which requirements = DIE TRAGSCHIENE = must fulfil exactly. The production department of the partner company for manufacturing demands precise instructions on what has to be done.

For a long time I had been looking for a suitable solution to simplify control cabinet assembly and wiring. My studies in plastics technology at the University of Applied Sciences Northwestern Switzerland gave me the necessary tools for an in-depth analysis of the requirements and feasibility.

Ideas become plans, plans become market-ready products. Now is the time for the new mounting rail. Join us, become part of this further development!

2023: Patent granted CH716817B1

2021: Utility model DE202020005656U1

2019: Putting theory into paractice together with well known Swiss company for manufacturing

April 2019: Graduation with the Master's Thesis «Analyse der Machbarkeit einer Tragschiene TH35-7,5 nach DIN EN 60715 aus Kunststoff (Substitution von Metall)»